The primary target of the flame scanner is to alert operators about combustion instability situations. Which could potentially lead to the accumulation of unburned fuel and potential hazards for plant operations.

ABB has developed various flame scanners designed for accurate detection (flame on / flame off) of the burner flame. While preforming an evaluation of the flame quality and temperature of a variety of fuels. Flame quality can be measured on the flame strength levels which can be sent in either analog or standard digital formats for networking to a centralized plant control or SCADA system. There is where the data can be analyzed to improve plant combustion effectiveness, thermal efficiency and to reduce fuel consumption while lowering emissions.

Advantages of ABB Flame Scanners:

- Accuracy & Precision

- Saftey

- Diagnostics

- Cost Savings

- Nuisance free operations

- Reporting

- Setup

Applications:

- Main Boilers

- Heaters

- Furances

- Industrial Boilers

- Main Burners

- Burners

- Kilns

- Fire Stacks

Industry’s:

- Power Generation

- Oil & Gas (Refineries)

- Chemical & Petrochemical

- Pulp & Paper

- Minerals

- Metals

- Waste Incinerators

- Flare Stacks

SF810i Integrated Flame Scanner

The SF810i integrated flame scanner and signal processing unit incorporates the latest automation technology and requires less hardware to provide safe and reliable boiler operations. SF810i unique feature is “Integrated” meaning that all electronic components such as sensors, wire terminals, processing unit, relays and communication are all enclosed in the scanner. It is easy to install and has straightforward configuring in the Flame Explorer. Assembled with a sensor to detect the following flame (IR; VL; UV; UVIR; PYR). The SF810i is a “single flame unit”.

SF810-PYRO & SF810i-PYRO:

On top of basic functions of both flame scanners offer the “Live Flame Temperature” reading and a valuable input to improve the total NOx reduction by monitoring the combustion process. Online or remote temperature reading and monitoring or configuring with Flame Explorer software. The two color or dual wavelength will allow detection and measurement even if something obscures the line of sight such as smoke, dust or partials.

FAU810 & SF810 Conventional flame scanner:

These flame scanners are easy to install and flexible to operate in hazardous areas. Built with explosion proof case and assembled with a single or dual sensor depending on which flame you need to detect. Options are: (IR; UV; UVIR; PYRO). FAU810 &SF810 models target updating outdated flame scanner systems weather they are old and outdated or faulty scanners that might have separate scanners and analysis units.

Flame Explorer:

The Flame Explorer software is for configuration, data trending and a historian database. These are great for plant engineers and or operators for monitoring. The Flame Explorer software is compatible with ABB Flame scanners and has security against unauthorized users for modifying the parameters. Advantages of the software are using the archiving, trending, playback, reporting, setup of Scanner and tuning remotely or changing parameters. Can support up to 64 scanners. Tracks and Trends the following: DC Intensity, Flicker frequency, AC amplitude, Flame Quality, Flame Temperature and the current flame state relay.

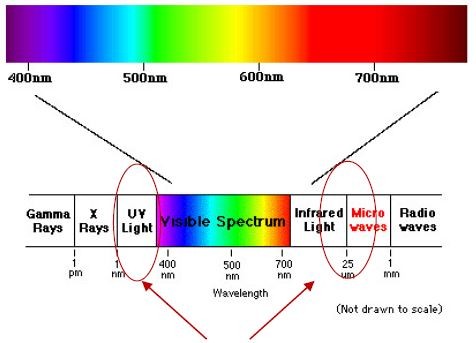

UR and IR Wavelength

Why is UR and IR wavelength important in figuring out what Flame scanner would best fit your application?

With all the different types of fuels they each burn at a different range which in turn creates a different wavelength in which is best for a flame scanner to see the flame and monitor its detection and read the temperature and all the information that is needed to keep accuracy, precision, efficiency, and safety at the operational facility.

UR (Ultraviolet Radiation)

Ultraviolet is detected at: 100-400 nm

IR (Infrared Radiation)

Infrared is detected at: 760-780 nm to 1 mm

Visible Light Specturm

Visible Light Spectrum is detected at: 400nm- 780nm

Complete BMS Offered: